Table of Contents

Introduce automation to increase profitability in your manufacturing business.

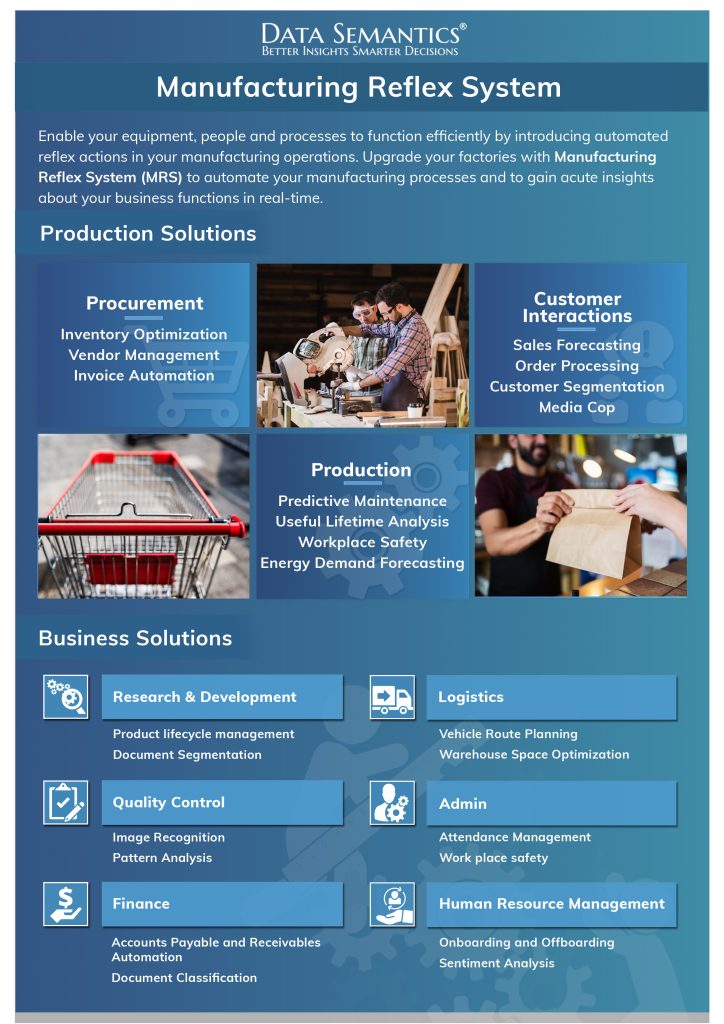

Enable your equipment, people and processes to function efficiently by introducing automated reflex actions in your manufacturing operations. Upgrade your factories with Manufacturing Reflex System (MRS) to automate your manufacturing processes and to gain acute insights about your business functions in real-time.

Employ our world-class Artificial Intelligence and Machine Learning algorithms that deliver supremely automated and highly accurate results for a wide spectrum of use cases in manufacturing industry. Employ yourself, only for effective decision making; not to perform mundane tasks.

[sf_button colour=”accent” type=”standard” size=”large” link=”https://datasemantics.co/contact-us/” target=”_blank” icon=”” dropshadow=”no” rounded=”no” extraclass=””]Contact Us to Know More[/sf_button]

[sf_button colour=”accent” type=”standard” size=”large” link=”https://datasemantics.co/contact-us/” target=”_blank” icon=”” dropshadow=”no” rounded=”no” extraclass=””]Contact Us to Know More[/sf_button]

Featured Solutions of Manufacturing Reflex System

1. Predictive Maintenance

Utilize assets to maximum potential

Highly accurate Predictive Maintenance models have proven to help our clients in several industries to achieve high-asset-utilization and savings in operational expenditure. Our predictive maintenance solution accurately predicts if or when an equipment failure may occur and further suggests preventive measures to perform maintenance.

2. Useful lifetime analysis of engine

Foresee the life of your valuable machinery

Predict the life of your machinery and utilize your machines to their full potential by using our highly accurate useful lifetime analysis solution. Calculate risks at an early stage and save your financial plans from unforeseen investments in your equipment.

3. Predictive Maintenance with IoT/Sensor data

Track the health status of your machines in real-time

Evaluate the performance of your machinery, equipment and important assets in real-time by using smart IoT condition-monitoring systems. Install and deploy predictive maintenance sensors based on IoT to monitor the status of your equipment and to save your business from multiple operational losses.

4. Employee Attendance

Track your employees effortlessly in real-time

Automatically register the attendance of your employees and track all the employees on the shop floor in real-time. Reduce dependencies on tedious legacy systems and upgrade to a simpler and effective attendance system using Facial Recognition.

5. Workplace Safety

Make your factories safer than ever

Track the safety of your employees by making using our Facial Recognition technology in your factory. Receive real-time alerts if either of your workmen are not following the safety protocol by ignoring any safety measures.

6. Document Classification

Employ humans for better tasks

Automate the process of archiving your documents to make them easily accessible across digital platforms. Avoid utilizing redundant human resources for manual work and make your documentation processes highly organized.

7. Invoice Automation

Avoid errors and reduce losses from inaccurate invoicing

Automate your Accounts Payable process by using our Invoice Automation systems to reduce redundant human efforts and to avoid human errors. We employ our highly accurate Machine Learning (ML) algorithms and Natural Language Processing (NLP) systems to deliver error-free automation.

8. Business Intelligence

Listen to your business insights in real-time from anywhere

Gain valuable insights about your business operations in real-time from anywhere. You can choose to read your business insights or listen to them from your personal voice assistant, anywhere.

Benefits of Manufacturing Reflex System

1. Allows focused decision-making

Focus on important decision-making rather than, investing your precious time in worrying about your machinery, documentation or business processes.

2. Predicts threats or anomalies

Predict the lifetime of your equipment or foresee any anomalies in your machinery at your manufacturing plants by upgrading.

3. Makes operations safe and secure

Track workplace safety of your people at the shop floor and be aware of any threats in real-time. Protect your shop floor from any unauthorized access and get notified about such threats immediately.

4. Keeps you up-to-date

Have all the important information about your manufacturing business at your fingertips. Stay updated in real-time about your business operations.

[sf_button colour=”accent” type=”standard” size=”large” link=”https://datasemantics.co/contact-us/” target=”_blank” icon=”” dropshadow=”no” rounded=”no” extraclass=””]Contact Us to Know More[/sf_button]